This page has been automatically translate with Google from the Italian language.

CHAPTER IV Case of study: modellizzazione of one Manufacturing Supply Chain

4.11 Behavior of the production model

In order to begin to test the model table 4.8 extension the parameters that will be considers you like constants

for a manifacturing company.

Figure 4.8- Parameters of base for the productive model

While “Minimum order processing Time” is 2 weeks, the company wishes an emergency stock (safety stock) of 2 weeks

adds them of cover. Given the values for order fulfillment function, inventory coverage, equal to the minimum order processing

Time it would turn out, in a level of service of 85%.

Adding a stock of equal emergency to 2 weeks it adds them of waited for question (expected demand) means that the shipment

rate maximum (maximum shipment installments) would be 2 times the wished rate when inventory he equals its wished

level, qualifying the company to fill up 100% of the orders.

This first simple model that regards the management of the warehouse without to still consider the management and the finding

of the materials and the back orders to you has been implemented with Powersim and the structural diagram is brought back in figure 4.9.

Figure 4.9- Structure of the management of the warehouse

Like approval for the example of the previous understood one it, through the chosen software of simulation it is possible to visualize through

time diagrams the course of the variable ones, that they constitute the structure of the system, and therefore to be able some to study

the behavior.

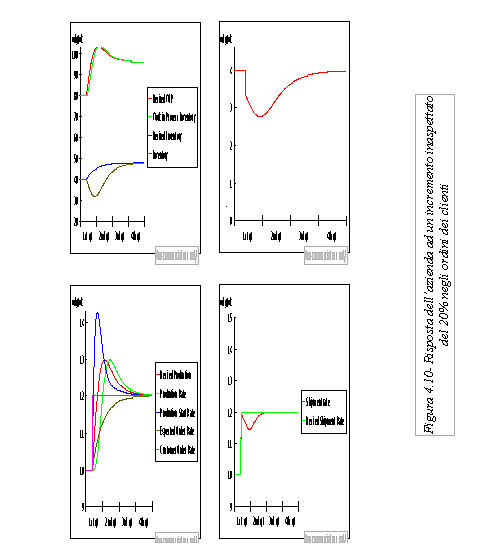

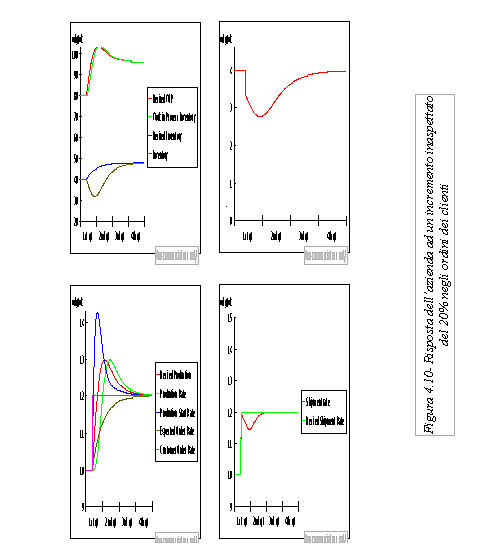

Figure 4.10 extension the answer of the company to an unexpected increment of 20% in the orders of the customers.

It begins them customer order installments is of 10 “widgets/week”. Desired shipment installments increases immediately after the unexpected increment

in question. Inventory coverage immediately falls from its begins them value of 4 weeks to 3.33 weeks.

In the moment in which customer order installments it increases, inventory still it is not changed, therefore Maximum Shipment Installments remains

same (the 20 widgets/week). The increment of the orders of 20% reduces the relationship between maximum and desired shipment from 2 to 1.67.

Order fulfillment ratio to this point is over 99%, therefore the company is initially able to cover nearly all

the entering orders, in spite of the increment.

However, since the continuous production to it begins them rate 10 “widgets/week”, inventory falls under the level begins them.

As inventory it falls, therefore the company is not more in a position to sending the goods. After approximately 7 weeks from the unexpected variation

of question, order fulfillment ratio comes down to 95% causing to the loss of transactions of the company (and its reputation like

reliable supplier).

The difference between the wished warehouse and that one puts into effect forces them desired production to raise itself above expected orders.

This makes that a difference between the level is opened puts into effect them and that one wished of WIP. Consequently, since WIP is increased

from production start installments, this grows ulteriorly above desired production installments.

With passing of the time the company recognizes that an accidental one rest begins it them increment in question is not and

its forecast of question gradually grows.

Given the 8 weeks of levelling for the forecast, it serves approximately average year in order to correct 95% of the management for

the new rate order.

In this period, the system cannot realize a balanced equilibrium: if inventory and WIP inventory had been equal

to their wished value, the production uguaglierebbe the forecast of the question, than, from the moment that is smaller of

the orders cause the fall of the warehouse.

As expected orders it grows, therefore ago also desired inventory, adding a difference between the warehouse it puts into effect them and that one

wished ulteriorly and increasing desired production.

Production starts catches up the maximum increasing of 42% approximately regarding the level begins them after approximately 4 weeks after

the unexpected increase of question.

The express increment in endured Production starts fills up the WIP supply but the production is behind of 8 weeks.

The production does not surpass shipment if not after that 6 weeks are passages; through this period of time inventory

it continues to come down in the same way in which desired inventory it grows.

Inventory stops to come down when the production uguaglia shipments.

However the system is not still in equilibrium because of the great difference between the wished inventory and that one puts into effect

them and between orders and expected orders.

Production eventually grows above shipments, provoking the increase of the warehouse, before that it catches up

eventually the new one, and more high, wished level.

To notice that the maximum of the production is caught up after approximately ¼ of year after the variation of the orders, much

more of the 8 chosen weeks like production delay.

The simulation of the system reveals some fundamental aspects of the behavior of one supplì chain:

- First, it begins it them answer of the company to an unexpected increment in the question is a decrease of the warehouse. The delay in the production (production delay) involves an unavoidable decrease begins them of the level of warehouse and is a fundamental consequence of the physical structure of the system. The reduction of the warehouse abruptly contrasts with desire of the company to hold more supplyes when the question increases;

- According to, the amplification of the unexpected increment of the question is unavoidable. Since the level warehouse must initially fall, the only way for increasing it to its begins them level and therefore to elevate it to the new one, plus high wished level is that one to make to exceed the production regarding shipments. Production must pass much above shipment installments in order to create a warehouse that equals the new wished level. Production starts must be still risen more so that the level than WIP it can be carried to a level consisting with a higher rate than productivity.

- Third party, the correction to the production catches up its maximum more or less when inventory it catches up its minimum. Inventory only touches the minimum after that the production finally has grown to equal shipments enough (shipments). This phase of characteristic delay of the greater part of the supplì chains, is one fundamental and unavoidable consequence of the physical structure of supplyes and flows.